Flotar – Recycled

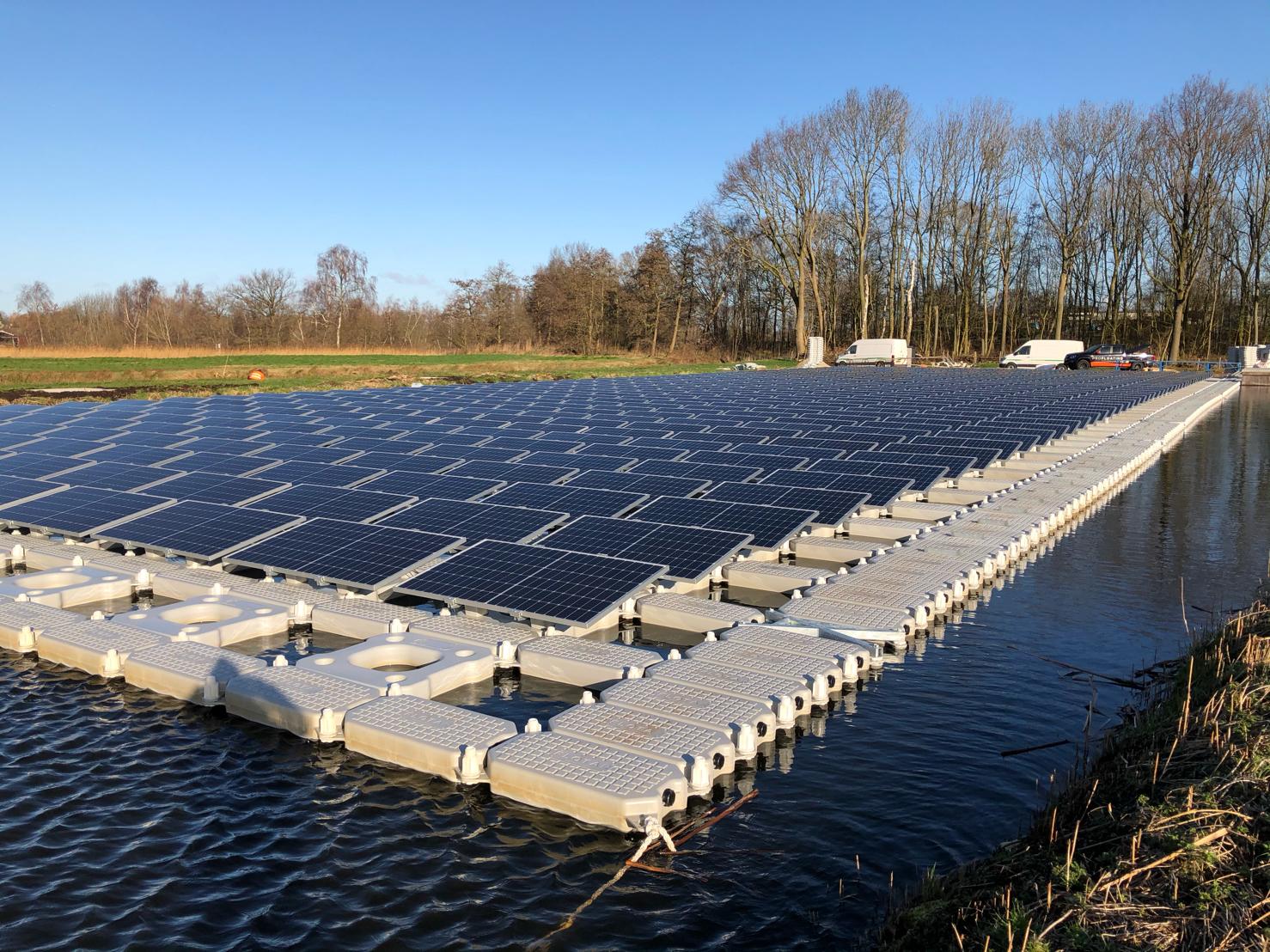

‘A floating system for placing solar panels above the water, developed in partnership with Profloating, and made out of 100% recycled plastics.’

Keywords: Mechanical recycling, TUV analysis, Product development (R&D + production)

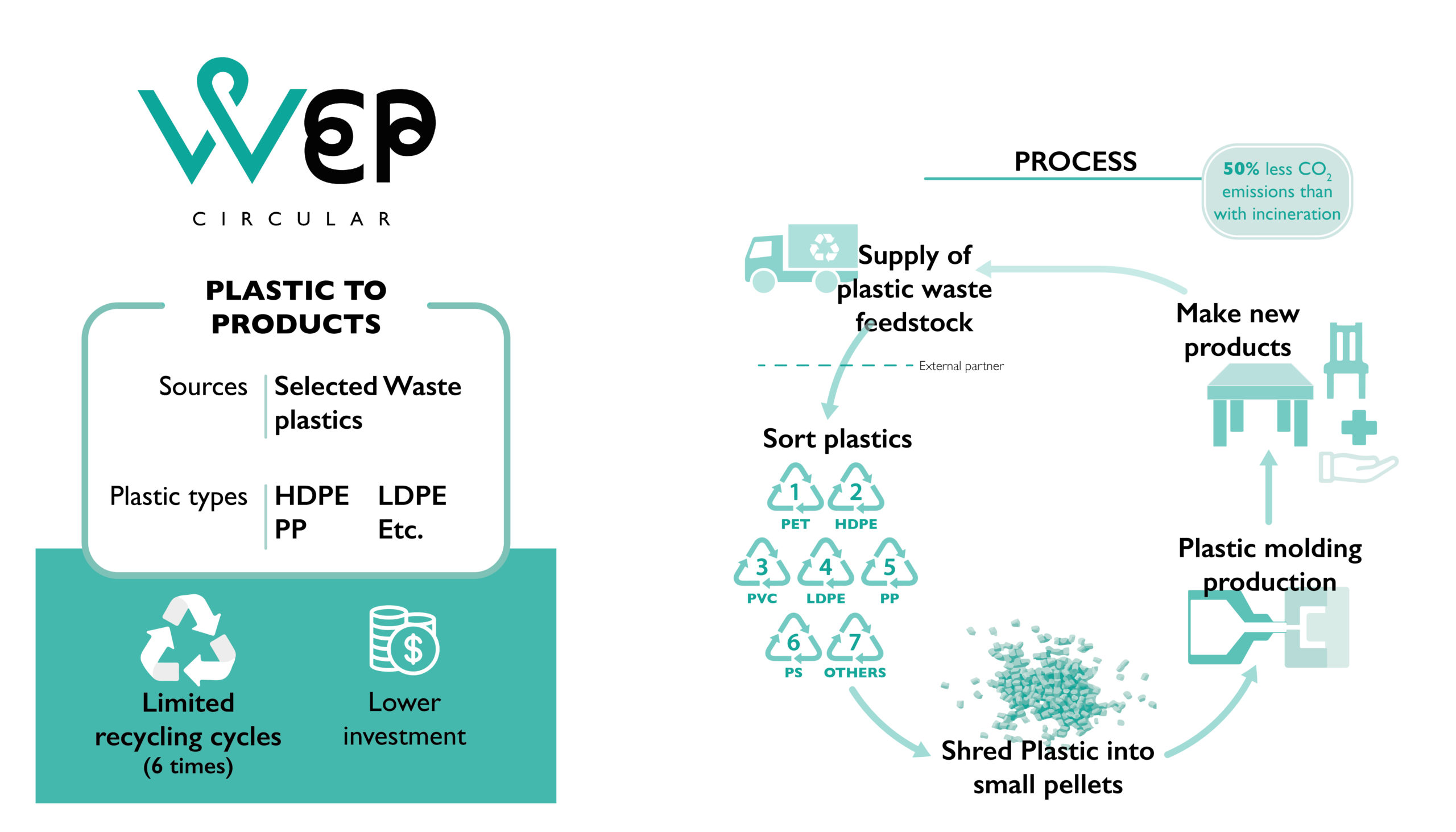

Having started as a non-circular project, our aim is to produce the whole floating system out of 100% recycled waste plastic, and to create a circular model. We have designed and produced some of the Flotar plastic floating elements out of 100% recycled waste plastic. The recycled ones contain 50% post-production waste and 50% post- consumer waste.

We analyse the performances of the recycled floating elements in our FlotaR&D lab and also have the material validated externally with research institutions (like TUV Rheinland) to proof quality and possibility that recycled materials are equal to virgin materials.

Our 100% Recycled HDPE plastic elements are TÜV Rheinland certified of having a long endurance and strength performance (>15 years) in harsh conditions of cold freezing weather and warm hot weather (Western Europe).

Flotar plastics elements produced of 100% virgin HDPE (sample 1) and elements produced of 100% Recycled HDPE (sample 2) have the same long endurance and strength performances.

See TÜV Rheinland report of Flotar weather and tensile testing